What Spare Parts Do You Need To Maintain A Pipe Threading Machine

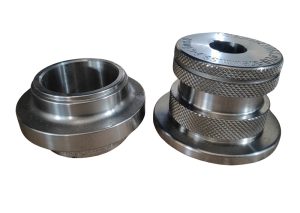

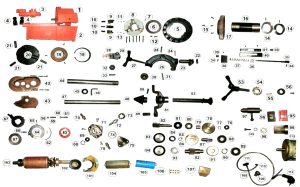

What Spare Parts Do You Need To Maintain A Pipe Threading Machine What spare parts do you need to maintain a pipe threading machine? For a heavy duty made in China pipe threading machine usually we offer one year warranty, while for a economic type pipe threader we offer 3 month warranty. After this period you will have to buy extra replacement parts to fix the machine. First of all, the threading dies(chaser) and cutting blade are wearing parts, regardless of wether the quality of machine is good or not you will have to prepare them. Normally a threading dies life span is hundreds of pipes, the life of the die depends on the material 9Cr2/9CrSi/HSS and production craft. Secondly, if you are an end user who purchased a pipe threading machine for your own use, buy a complete assembly parts will be easier for you to change old one. For example, you can buy a complete die head, a complete pipe cutter, pipe reamer, front chuck set, rear chuck set, motor, gear box, oil pump. This will solve 90% problem. However, if you would like to replace a single parts, you can refer to below chart (Chart No.1), this