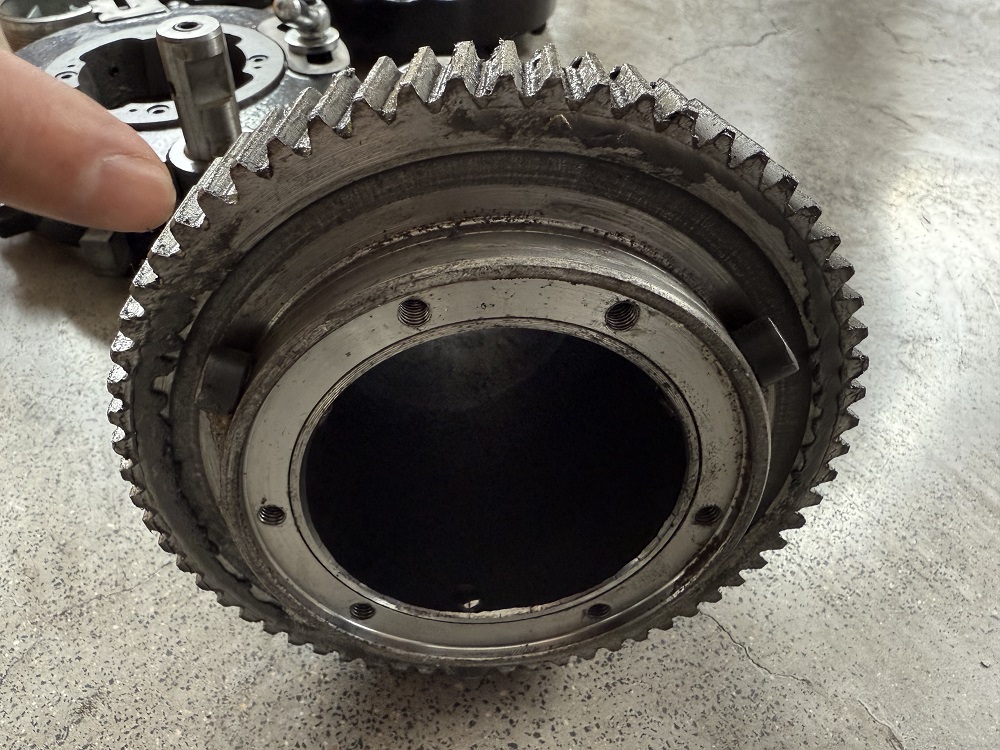

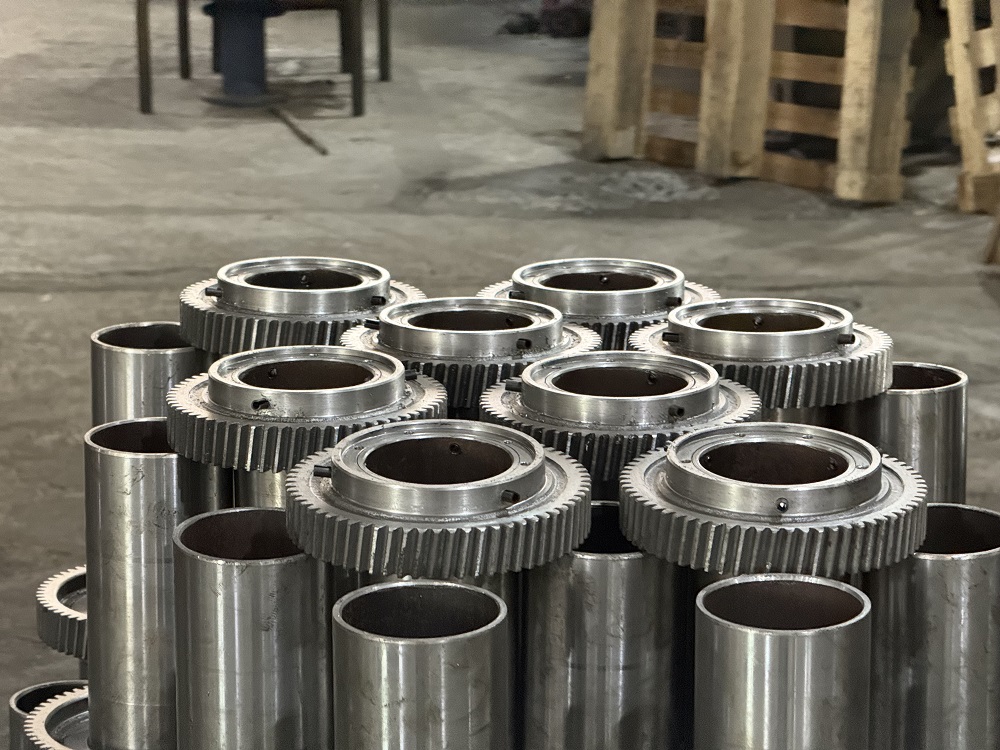

Why the big gear on pipe threading machine wear out fast?

The reason why the big gear component near the front chuck connected with hollow main shaft worn out fast is that wrong material of the gear used. Normally we use ductile iron as the material of the big gear of pipe threading machine. However, according to our test, ductile iron big gear work well with automatic self-open die head pipe threader, but not manual die head.

If your pipe threading machine are equipped with a manual quick-open die head, it is highly recommended to adopt forging iron as material to produce the big front gear of your electric pipe threading machine.