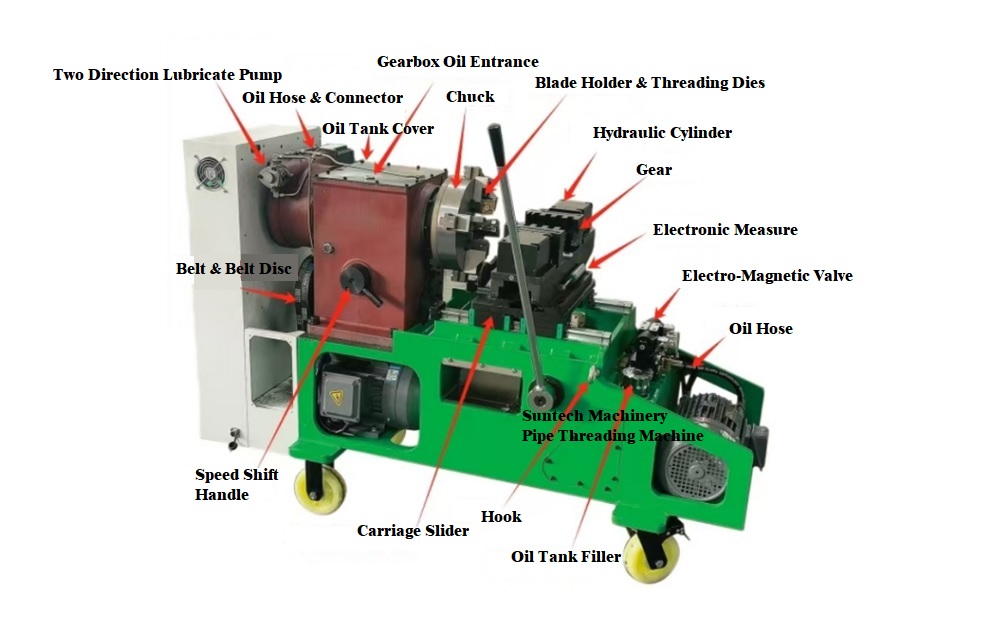

High Efficiency China Automatic Pipe Threading Machine Upgrade

We keep doing the high efficiency china automatic pipe threading machine upgrade for years.

Now it has come to the 9th generation. Compared with the prototype (1st gerneration), it is now

much more heavy duty and durable.

Basically there are below upgrade points for our automatic pipe threading machine.

1) The old hydraulic system is seperated type, while the new one is united type, which is more stable.

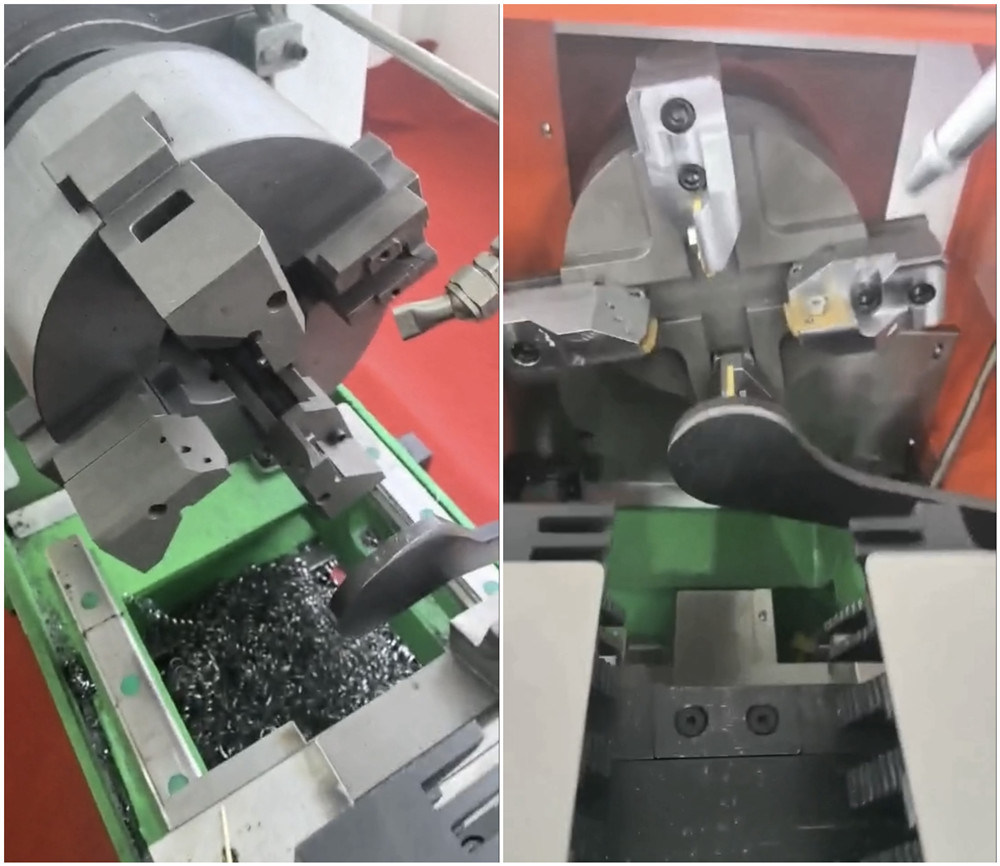

2) The threading scrap used to stuck in the front chuck on the old machine, but now in the new machine the chuck head is spiral type, so that the scrap will not drop in and stay in the chuck.

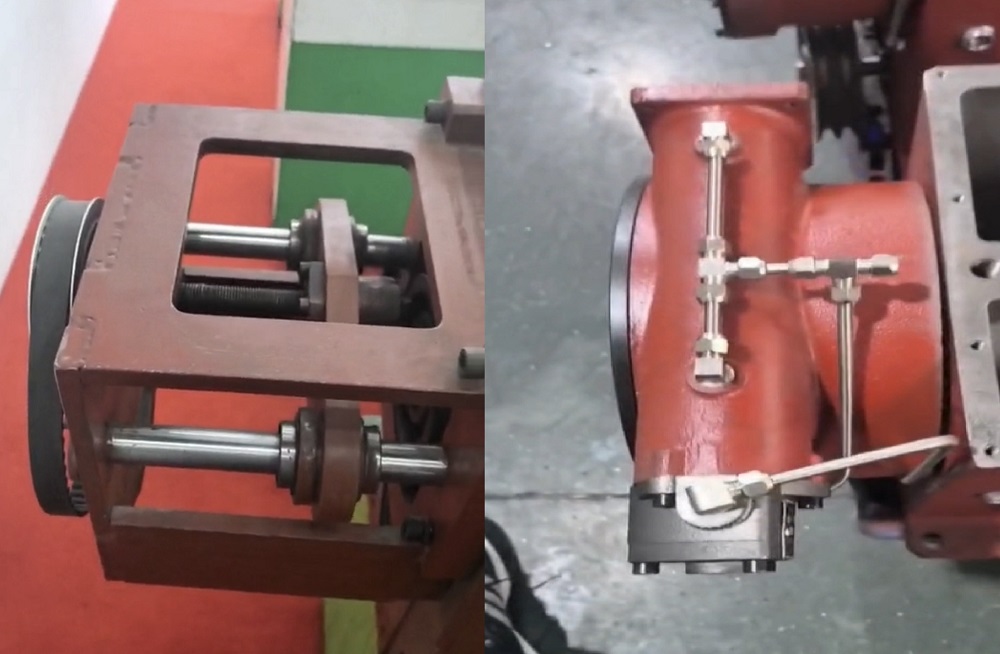

3) The old rear rack is pulling rod type every day worker need to add oil to it, while the new one is worm gear type there is no need to add oil everyday, the life span is much longer. The pulling rod type inside is screw rod and screw sleeve it is not precise and the two parts are made by different supplier. The new worm gear is customized from a single supplier and in high precision.

4) New machine is not only heavy duty but also light weight, it is now 530kgs compared with old one 870kgs, this is obviously easier to move.

5) Cooling water tank is now hidden inside, while the old one is outside the machine visible.

6) Before shipping we will run every gear box from our machine to make gear grinding with each other at least 12 hours to make sure the machine will run smoothly.