Elbow and tee PE pipe welding machine

- Good for welding plastic pipes and fittings made of PE,PP and PVDF.

- Welding position can be adjusted, it is convenient for welding different pipe fittings.

- Removable PTFE coated heating plate.

- Electric planing tool with safety limit switch.

Elbow and tee PE pipe welding machine

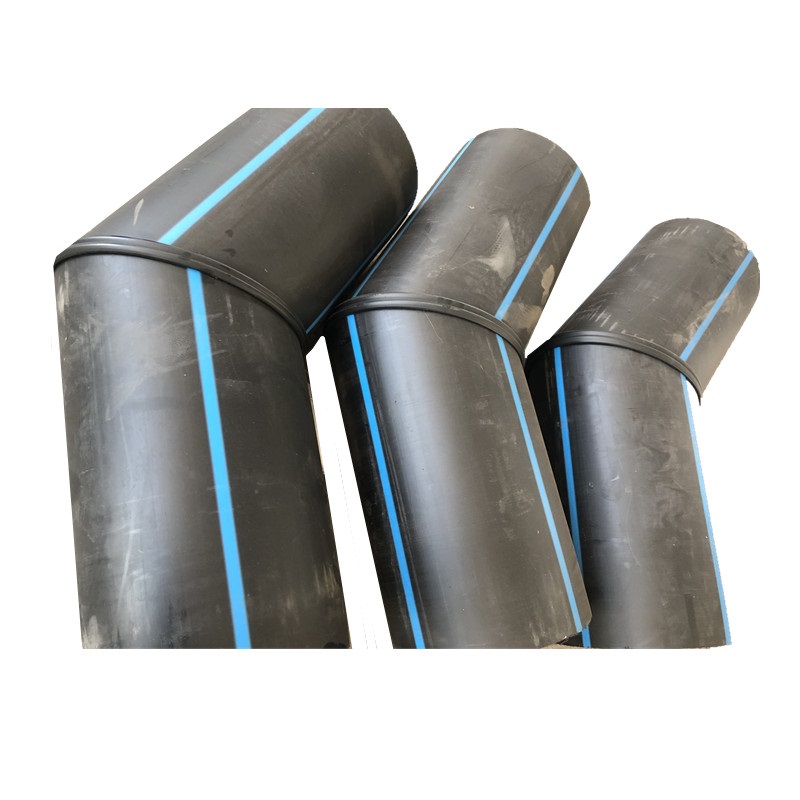

Elbow and tee pe pipe welding machine is special model of multi angle plastic pipe welding for elbow pipe and tee pipe welding. It works for all kinds of plastic pipe such as PE pipe, PP pipe, PB, PPR, PVEF, MPP material pipes and tube.

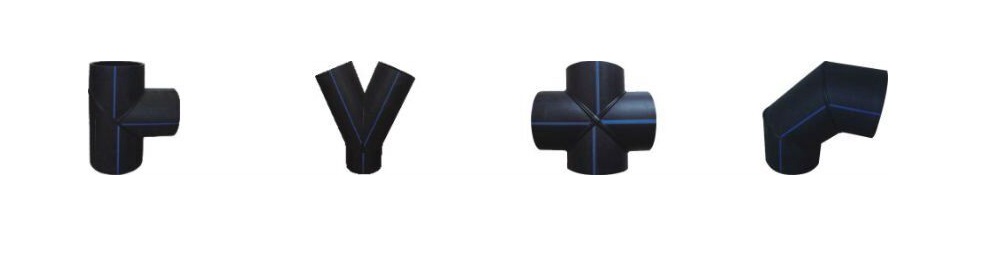

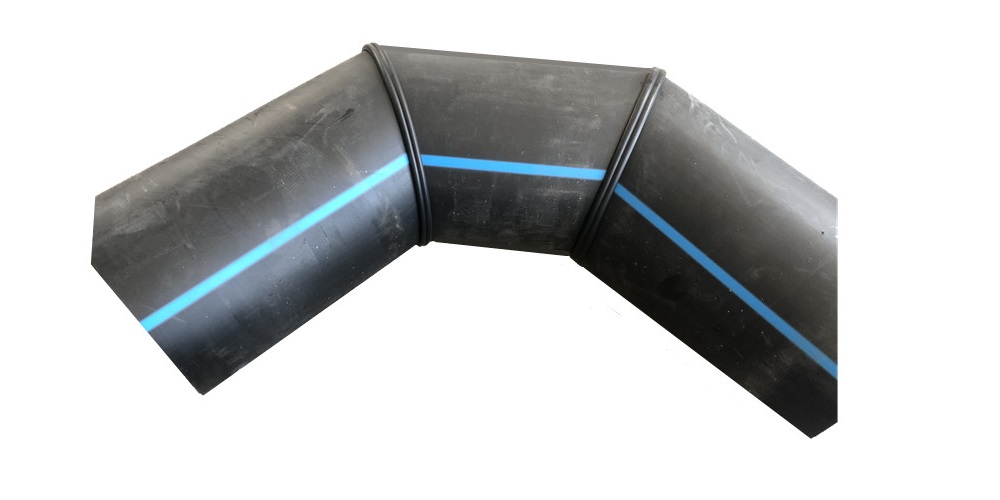

This machine is suitable for fabricating elbow, tee, cross and Y shape (45° and 60 °) fittings of PE PP PVDF in workshop. You need only to change the different special clamps while fabricating different fittings. Low starting pressure and high reliable seal structure. Separate two-channel timer records time in soaking and cooling phase. Digital pressure meter is installed on machines above SHG315.

| Model | SHG315 multi-angle butt fusion welding machine |

| Pipe Sizes | 90mm, 110mm, 125mm, 140mm, 160mm, 180mm, 200mm, 225mm, 250mm, 280mm, 315mm |

| Application | 0~90°elbow, tee, cross, 45° and 60°Y (optional parts should be used) |

| Heating Plate Max. Temp. | 270°c |

| Temp. deviation in surface | ±5°c |

| Pressure adjustable range | 0-10Mpa |

| Working Voltage | 380V,50Hz/60Hz |

| Heating Plate Power | 5.15KW/380V |

| Hydraulic unit power | 1.5 KW/380v |

| Planing tool/Milling cutter power | 1.5 KW/380v |

| Total Power | 8.15 KW/380v |

| Total Weight | 800KG |

Heating plate

1. Teflon coating material used on this welding machine are imported from Japan, the plate produced by twice coating and three processes.

2. The solid core of the heating plate is thickened and tube will not stick to it, the heat transfer is good and it ensure the contact safety of the power supply.

3. Compared with other manufacturers, the thickness of our heating plate is increased by 5mm, and the heat storage and thermal conductivity are strong.

The hydraulic station

1. Timer, pressure gauge, temperature controller and alarm shall be installed on the operating table to facilitate observation and improve welding efficiency.

2. The temperature controller and pressure regulating valve are CE certified, and the control precision can reach 0.01%.

3. The hydraulic station is installed with an accumulator, which can realize the function of automatic pressure replenishment and reduce the number of manual pressure replenishment.

Planning tool / milling cutter

1. High power milling cutter, mirror cutter disk, strong motor, high concentricity, smooth milling.

2. High-power Bosch drill is adopted for milling motor, which is strong and strong without slipping

3. The milling cutter is equipped with a limited position switch, which can be rotated only when placed in the frame to prevent accidental injury.

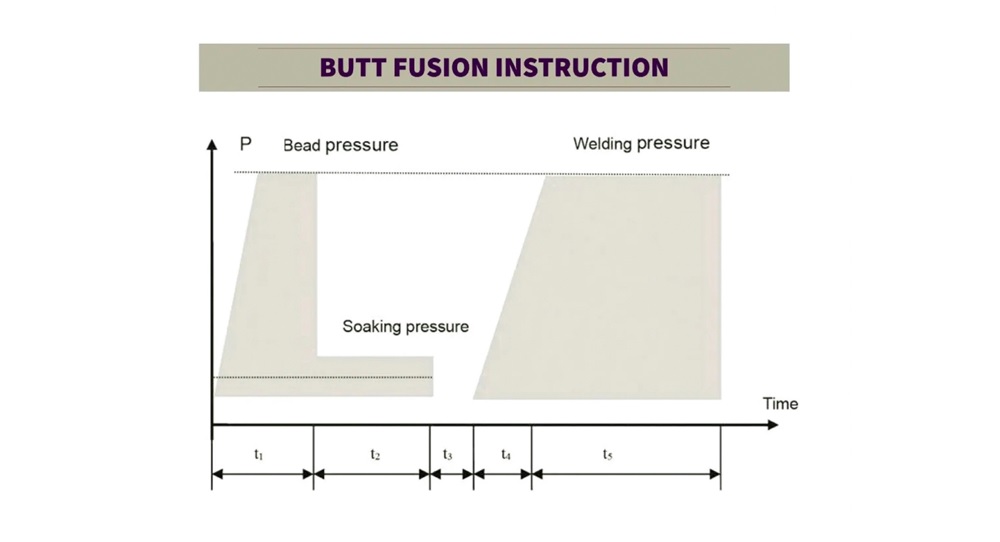

How to weld plastic pipes

1. Fix the proper clamps on the machine rack.

2. Insert the plastic pipe through the clamps and tighten the bolts.

3. Shearing the end of the plastic pipes with the planer.

4. Put the heater plate on the machine rack and heat the pipes in a proper period.

5. Remove the heater and connect the two plastic pipes.

| Wall thickness (mm) | Bead height (mm) | Bead build-up pressure (MPa) | Soaking time t2(sec) | Soaking pressure (MPa) | Change-over time t3(sec) | Pressure build -up time t4 (sec) | Welding pressure (MPa) | Cooling time t5 (min) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6-10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190~260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

| Bead build-up pressure and welding pressure in the form is the recommended interface pressure, the gauge pressure should be calculated with the following formula. | ||||||||

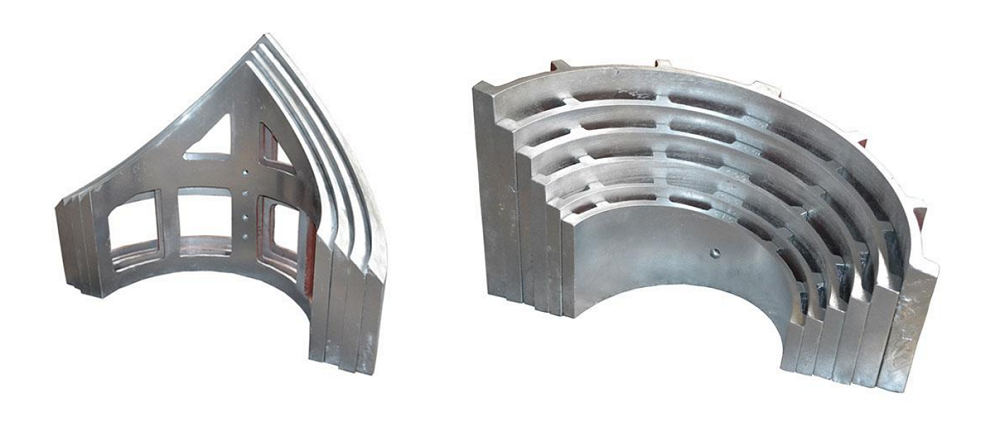

PICTURES OF ELBOW AND TEE PE PIPE WELDING MACHINE

F.A.Q.

We are professional pipe machine manufacturer located in Hangzhou city of China starts from 1989, we are close to Port Shanghai, Ningbo as well as Yiwu. We mainly export to North and South America, South Asia and the Middle East countries. Our client are power tools wholesaler and comnpany for specific constrution project such as fire fighting pipeline building etc.

We always test at least one pipe on every pipe machine before we ship out.

Some of our heavy duty models works well after even 7 or 8 years according to our client feedback, for all of our machine we offer 12 month warranty.

All kind of pipe tools and plumbing tools, such as pipe threading machine, pipe grooving machine, pipe cutting machine, pipe hole cutter, manual pipe bender, pipe vice as well as the test pump.

We focus on quality piping tools, machinery and service. We have almost all kind of pipe tools, place order to us we can mix different models in one shipment. Language available:English,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Since the voltage of machine motors are customized, usually the lead time will be 10-35 days after payment.

We accept T/T payment directly to our company account and we can also create order on the online shop site that you can pay to us by credit card.

We ship by sea to port for bulk order and we also ship to door for small shipment.

Basically there is no MOQ required for our machines, we can ship any quantity but it is highly recommened to make order amount not less than USD2000.00, because according to our experience if the order are too small amount the sea shipping adding tarrif makes it not cost-effective to buy oversea.

Yes. For bulk order we can make nameplate and customized packaging in client’s brand.

PRODUCTS CATEGORIES

Related products

-

hydraulic pipe butt fusion welding machine

Electrofusion pipe welding machine

Rated 0 out of 5Read more